How to identify container position on a ship?

Latest update on 29 April, 2024 by Aurora Park– Marketing Analyst at FreightAmigo

Container ships, pivotal in global trade, transport over 90% of non-bulk cargo worldwide, marking a revolution in commercial freight since the debut of the Ideal X in 1956. The identification of a container position on a ship is crucial for businesses to optimize container tracking and slots allocation, enhancing efficiency and reducing turnaround times.

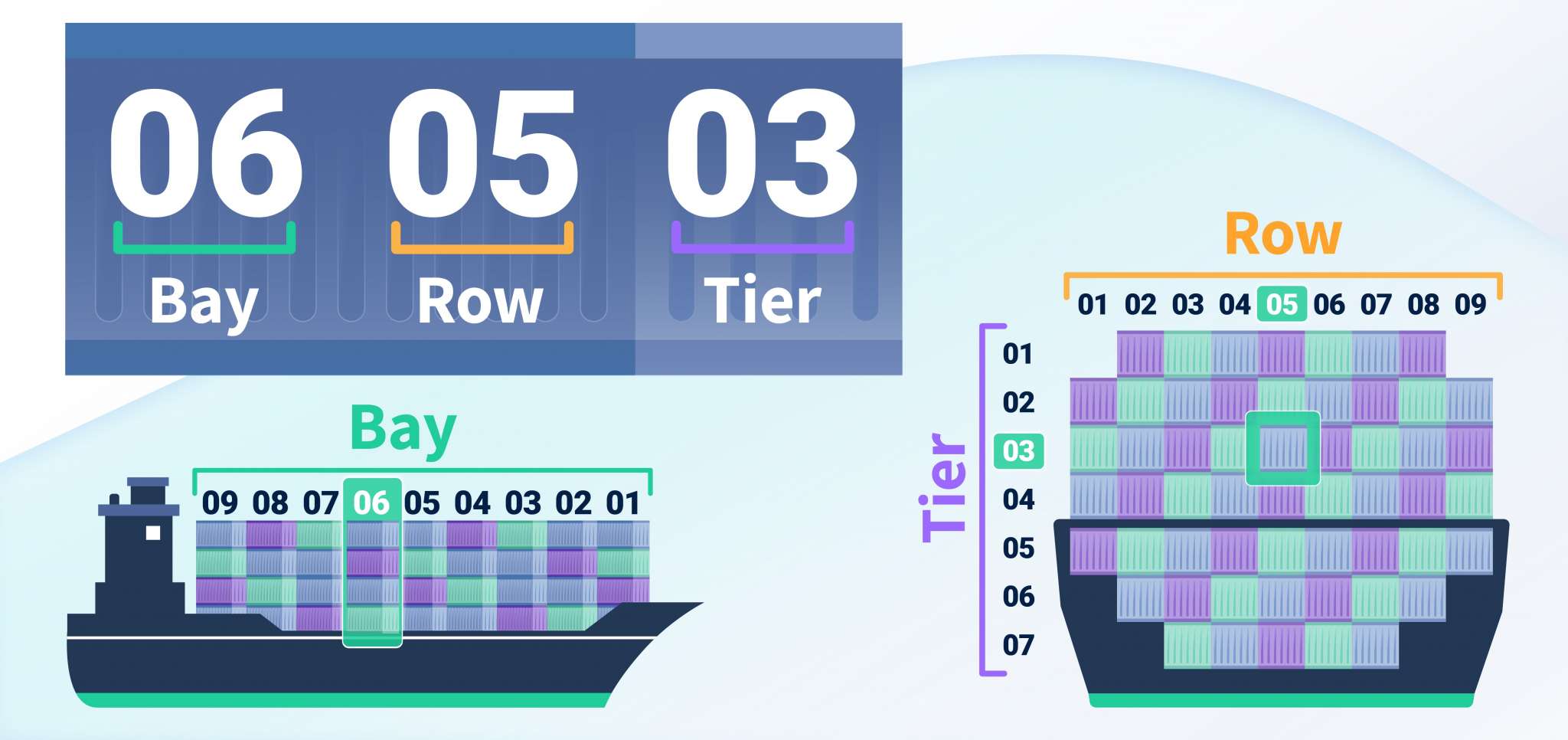

FreightAmigo will delves into introducing BAY-ROW-TIER numbering to you, a systematic approach for locating your container on the ship, and shares tips for efficient container tracking. It aims to simplify the complex process of container position identification and improve logistics operations.

Want To Compare The Best Express, Air Freight, Sea Freight, Rail Freight & Trucking Rates So As To Have Better Control On Cost?

Understanding BAY-ROW-TIER Numbering

-

Composition of the BAY-ROW-TIER System

The BAY-ROW-TIER system is a methodical approach to organizing containers on a ship. It comprises three main elements:

- Bay: Represents a vertical section of the ship, numbered from the bow to the stern.

- Row: Indicates the horizontal positioning across the ship’s width, with odd numbers on the starboard side and even numbers on the port side.

- Tier: Refers to vertical stacking of the containers, either above or below the deck.

-

Detailed Breakdown of Numbering

- Bay Numbers: Start from 01 at the bow and increase sequentially to about 40 at the stern.

- Row Numbers: Positioned across the ship’s width, using even numbers for the port side and odd for the starboard.

- Tier Numbers: Containers on the deck start at 80 and increase by two for each vertical layer, while those below deck start at 02, also increasing by two per layer.

-

Utility and Advantages

This system enhances the efficiency of container tracking and slots allocation by:

- Optimizing Space: Ensures every container fits into a designated slot, maximizing the use of available space.

- Improving Safety: Helps in preventing accidents by ensuring containers are properly stacked and secured.

- Facilitating Operations: Streamlines the loading and unloading processes, reducing turnaround times.

-

Integration with Technology

Modern shipping operations leverage software and technology, such as online trace & track, to refine the BAY-ROW-TIER assignments, considering factors like weight distribution, cargo type, and destination port. This integration aids in real-time tracking and management of containers throughout their journey.

By understanding the BAY-ROW-TIER numbering, stakeholders in the shipping industry can ensure a smooth and efficient handling of containers, significantly enhancing operational workflows and safety on board.

Locating Your Container on the Ship

Initial Steps in Container Location

- Reviewing Container Specifications:

- Length: Typically 20 or 40 feet, with some vessels accommodating 45-foot containers.

- Height: Ranges from 8 feet to 8 feet 6 inches, with high cube containers measuring 9 feet 6 inches.

- Width: Standardized at 8 feet.

- Identifying Markings:

- Containers display various codes and markings, including the container number, code, maximum gross weight, tare weight, and maximum payload.

Cargo Planning and Loading

- Cargo Plan Development:

- A team of central planners designs detailed cargo plans, aligning with the entire supply chain’s needs.

- Loading Process:

- Containers are loaded using cranes and stacked systematically, akin to building blocks, starting from the ship’s bottom.

Monitoring and Tracking

- Securing Containers:

- Port workers secure containers in place using heavy metal rods within cargo holds as large as 40 x 40 meters.

- Oversight by Ship’s Crew:

- The third mate oversees the loading and discharging operations, ensuring lashings are secure and monitoring the ship’s overall condition.

Advanced Container Tracking

- Using Online Tools:

- Track containers by entering the container number on tracking platform like FreightAmigo Track & Trace, which can automatically detect the shipping company.

- Tracking Options:

- Users can choose between detailed tracking with additional tools or direct tracking for straightforward status updates.

Conclusion

Through the detailed exploration of container positioning on ships—from the intricacies of the BAY-ROW-TIER numbering system to the advanced tracking technologies—this article has aimed to demystify the logistical challenges faced by stakeholders in the shipping industry. By understanding and utilizing the strategies outlined, businesses can optimize their container tracking, enhance operational efficiency, and secure their cargo, ensuring it reaches its destination safely and in a timely manner.

For those looking to streamline their container positioning and tracking further, exploring platforms such as FreightAmigo offers a seamless way to integrate these processes into your operations. In the end, the goal is not just to move goods, but to do so in a way that is efficient, secure, and adaptable to the changing dynamics of global trade.

If you wish to learn more about container or cargo shipping, Please Go To FreightAmigo Page For Inquiries

Read more:

【Shipping 101】 TEU= Twenty Feet Equivalent Unit?

Size Matters: How Shipping Container Sizes Impact the Container Shipping Industry

What are the 11 most common container types?

Simplify Your Freight Shipping with the Freight Class Density Calculator | FreightAmigo

If you have any inquiries on logistics / supply chain, feel free to contact FreightAmigo now:

Chat with us online | Hotline: +852 28121686 | WhatsApp: +852 27467829

![京東物流本地物流[香港] 服務一覽](https://www.freightamigo.com/wp-content/uploads/2024/04/JDL-2-300x300.png)